Timing Screws and Feed Screws: Frequently Asked Questions.

Jun 23, 2025

At Septimatech, we frequently get questions about timing screws and feed screws. To help you better understand how to get the most from your timing screws and feed screws, from initial inquiry to installation on your line, we’ve compiled answers to some of the most frequently asked questions:

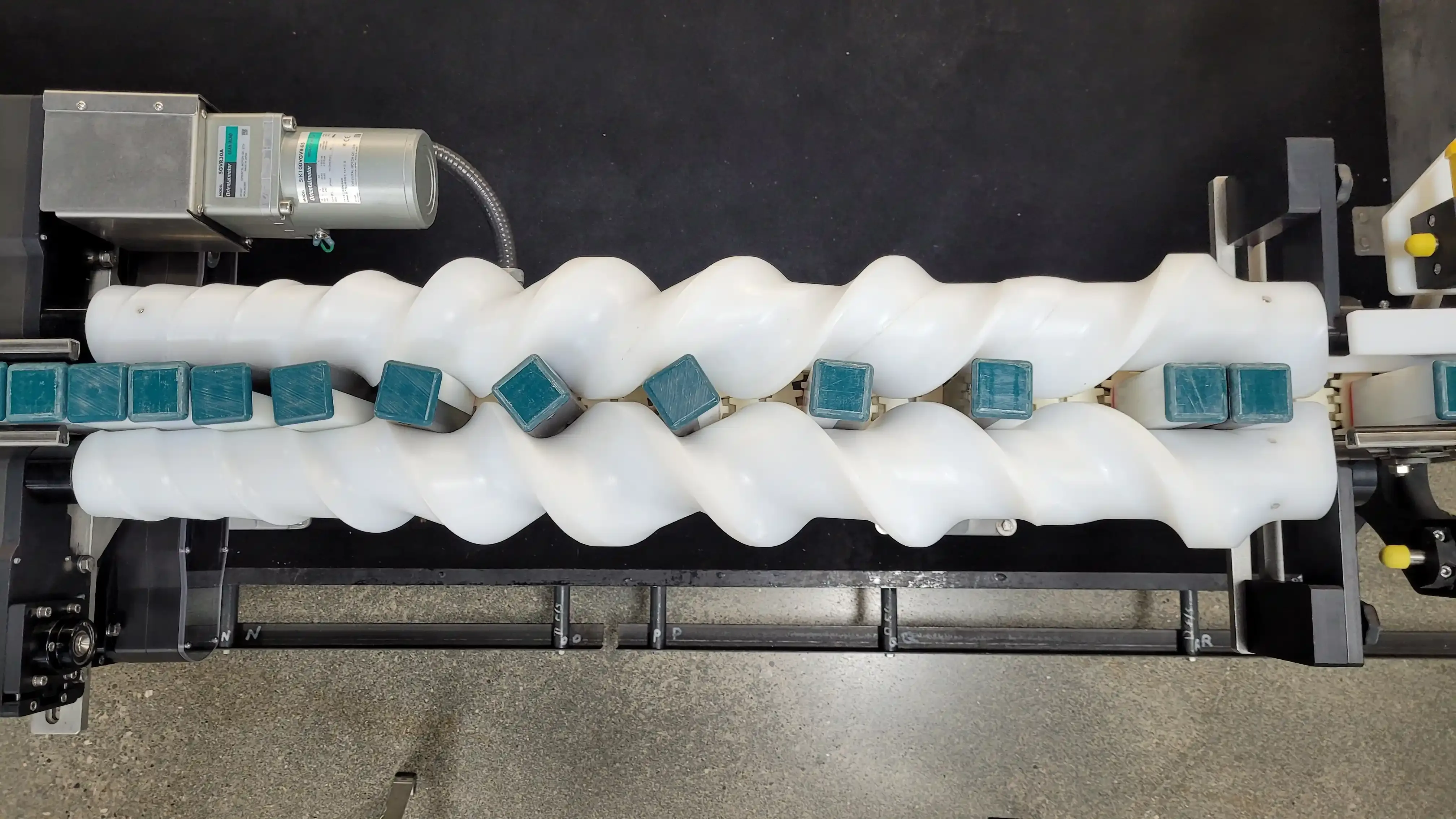

What is the Purpose of a Timing Screw/Feed Screw?

Timing Screws (also called feed screws, scrolls, worms, helix etc) are crucial components on packaging lines, as used to control the spacing, orientation, and timing of containers as they enter, exit, or transfer between packaging machinery, like fillers, cappers, labelers, air cleaners, case packers, and many other machines.

Timing Screw systems from Septimatech are designed and built to help end users achieve high quality container handling, while maximizing throughput and changeover efficiencies. Our timing screws ensure containers and cartons are precisely timed to support the speed, accuracy, and efficiency of your line, while reducing product damage and downtime between changeovers.

What Types of Containers Can Septimatech make Timing Screws for?

Septimatech’s engineering team is made up of world class engineers, some of whom have been designing feed screw solutions for over 30 years. Septimatech Feed Screws can accommodate virtually any type of container, carton, or other product, just some of which are included in the list below:

- Bottles, both glass and plastic

- Jars (for food items like pickles, sauces, and much more)

- Cans (tall cans, sleek cans, aerosol cans)

- Small, pharmaceutical type vials

- Larger containers, like jugs of washer fluid

- Cartons

- Cups (like fruit cups)

- Many more..

Not sure if your container will work within a feed screw system? Please feel free to reach out regardless! Our engineering team is always assessing new container types, furthering our capabilities to provide a wide array of applications for many bottle and container types. Custom feed screw solutions from Septimatech are ideal for industries like food and beverage, pharmaceuticals, personal care, household products. But we have many custom solutions to fill various applications in case a feed screw may not be sufficient for yours!

How Fast Can I Change Over to a New Container Size?

Septimatech Feed Screws are designed for fast, tool-less changeovers, reducing setup time from hours to just minutes. Our quick change feed screw drive systems allow operators to quickly change out screws for new formats without the need for fine-tuning or technical expertise.

What Makes Septimatech Feed Screws Different from Other Feed Screw Providers?

At Septimatech, we deliver:

- Specialty manufacturing for custom finishing requirements.

- Custom-engineered solutions tailored to your container’s unique shape, no matter the complexity of the application.

- Intuitive Quick-Change Design for operator ease-of-changeover and consistent setup when paired with a Septimatech Feed screw drive system.

- Application-focused timing screw solutions to automate manual processes on your packaging lines, aiding in reducing production challenges due to labor.

Can Septimatech Integrate Feed Screws with Existing Equipment?

Our engineering team works closely with both OEMs and end-users to seamlessly integrate feed screws and feed screw drives into new or existing packaging equipment — conveyors and machines alike — without the need for major modifications. If you are working with older legacy filling machines or using the latest packaging automation technologies, rest assured knowing that Septimatech can provide you with a custom solution that match your machine specifications and application requirements.

Our team takes the time to understand your line layout, application requirements, and production goals to ensure the feed screws we provide exceed your expectations. Our goal is to future-proof your packaging line with solutions that grow with your production needs.

How Do I Know If I Need a Single or Dual Feed Screw System?

If your line handles products of significantly different shapes or sizes, or if you need to precisely group containers for downstream operations (such as multi-packing or labeling), a dual feed screw system may be ideal.

Septimatech will work with you and together we can assess your application needs and come to the right solution.

Dual screws provide enhanced control and synchronization, allowing for advanced manipulation of containers to improve throughput, reduce rejects, and minimize line disruptions. Septimatech works closely with you to evaluate your product mix, speed requirements, and line layout to engineer the most efficient, scalable system tailored to your needs. Our feed screw solutions are designed for adaptability and built to grow with your production.

How Durable Are Septimatech Feed Screws?

Manufactured from materials that are abrasion resistant, Septimatech Feed Screws are built for longevity even under the most demanding operating conditions. Our focus on reliability and repeatability means fewer maintenance issues and lower total cost of ownership.

Ready to Get Started with Septimatech Timing Screws?

Our process is simple and customer-focused:

- Consultation: We work with you to understand your challenges and applications specific needs.

- Design & Manufacturing: Our engineering team will design a precision feed screw system that will then be manufactured in house and shipped directly to your site.

- Support: Our experts remain available to optimize your performance long-term.