Container Handling for Multiple Container Sizes on a Packaging Line:

Running five different bottle sizes on a single packaging line sounds efficient until the third changeover of the shift takes 45 minutes and production targets start slipping. The challenge isn't whether a line can handle multiple container sizes, it's whether it can switch between them without losing half the day to adjustments and troubleshooting.

Products On Display - Pack Expo East 2026

Looking to Boost Efficiency and Maximize Output with Fewer Resources? Discover how Septimatech’s advanced Changeover and Container Control Solutions can help you reduce downtime, optimize labor, and accelerate production, only at Pack Expo East 2026.

How to Improve Changeover Efficiency in Packaging Operations in 2026

Every minute your packaging line spends in changeover is a minute not producing saleable product, with manufacturing downtime costing $50,000 per hour for the average facility. For operations running multiple format changes per shift, those minutes compound into hours of lost capacity each week.

Septimatech Group Inc. Partners with Magnetic Technologies on Capping Solutions.

Septimatech Partners with Magnetic Technologies to bring its Customers leading technology for Rotary Capping Machines that will improve changeover efficiency and give machines new life.

5 Great Reasons to Upgrade Your Change Parts in 2026

For some packaging operations, the decision to upgrade change parts is an afterthought until it’s time to run new containers or something breaks. Efficient interaction between your packaging machines and your containers depends on your change parts. Investing in them...

What are Adjustable Guide Rails for Conveyors?

In the precise world of packaging, repeatability, flexibility, and efficiency during changeovers are indicators of effective and productive packaging lines. One often-overlooked contributor to seamless packaging line performance is the adjustable guide rail system.

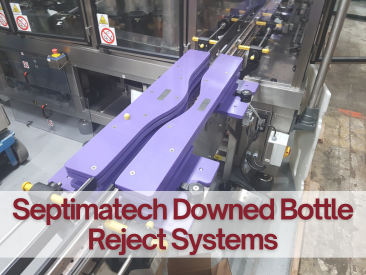

Keep Production Moving: Eliminate Downtime with a Downed Bottle Reject System

Septimatech’s Downed Bottle Reject System is engineered to identify and remove fallen containers before they become a problem—ensuring uninterrupted production and consistent output.

Timing Screws and Feed Screws: Frequently Asked Questions.

At Septimatech, we frequently get questions about timing screws and feed screws. To help you better understand how to get the most from your timing screws and feed screws, from initial inquiry to installation on your line, we’ve compiled answers to some of the most frequently asked questions:

Products On Display - Pack Expo Las Vegas 2025

Looking to Boost Efficiency and Maximize Output with Fewer Resources? Discover how Septimatech’s advanced Changeover and Container Control Solutions can help you reduce downtime, optimize labor, and accelerate production—only at Pack Expo Las Vegas 2025.