How to Improve Changeover Efficiency in Packaging Operations in 2026

Jan 13, 2026

Every minute your packaging line spends in changeover is a minute not producing saleable product, with manufacturing downtime costing $50,000 per hour for the average facility. For operations running multiple format changes per shift, those minutes compound into hours of lost capacity each week.

The difference between an hour long changeover and a 5-minute changeover often comes down to method and equipment rather than operator speed. This blog will cover the practical strategies, SMED principles, and equipment solutions that can help your packaging operations reduce changeover time and get more throughput from existing lines.

What Is Changeover Time in Packaging Operations?

To improve changeover efficiency, the most effective approach combines SMED (Single-Minute Exchange of Die) principles with practical equipment solutions. The idea is to separate tasks that require the line to stop from tasks that can happen while production continues, then streamlining whatever remains. On packaging lines, this generally means focusing on adjustable guide rails, organized change part storage, standardized procedures, and consistent operator training.

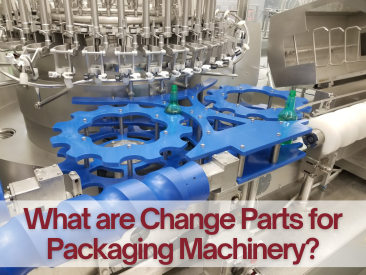

Changeover time is the period when a packaging line stops producing one product and prepares to run another. This window includes swapping change parts like timing screws and starwheels, adjusting guide rails for different container sizes, clearing the line of previous product, and verifying the new setup before production resumes.

Changeover Time vs Setup Time:

These terms often get used interchangeably, though they describe different situations. Setup time refers to preparing equipment before any production begins, usually starting up for the first time after maintenance or installation. Changeover time covers the transition between production runs when you're switching formats, products, or container sizes mid-shift.

Why does Changeover Efficiency Matters for Packaging Lines?

Consumer packaged goods companies are facing increasing pressure to handle more SKUs, smaller batch sizes, and faster response to ever-evolving market demands. Every minute spent in changeover is a minute not producing product, and those minutes add up quickly across multiple daily format changes. Improving changeover efficiency can do the following:

Increase Throughput and Output:

- Shorter changeovers translate directly to more available production time. A line running three changeovers per day at 45 minutes each loses over two hours of production. Cut those changeovers to 15 minutes, and you've recovered 90 minutes of capacity without purchasing new equipment or adding shifts.

Greater Production Flexibility

- When changeovers are fast and predictable, scheduling becomes far more flexible. You can run smaller batches economically, respond to urgent orders, and handle seasonal product variations without the penalty of extended downtime eating into your margins. Operations requiring frequent changeovers particularly benefit from this increased flexibility.

Reduced Labor Costs and Operator Strain

- Streamlined changeover equipment and processes reduce the physical effort and specialized knowledge required. Operators spend less time making repetitive adjustments and more time on higher-value activities like quality monitoring and troubleshooting.

Interested in streamlining your Changeovers?

What Actually Impacts Changeover Time on Packaging Lines?

Before jumping to solutions, it helps to identify what's actually causing slow changeovers. The root causes typically fall into a few common categories.

Complex Manual Adjustments:

- Guide rails that require loosening dozens of brackets along the entire conveyor length, or equipment that demands precise measurements and trial-and-error positioning, will always extend changeover duration. Each adjustment point adds time and introduces variability between operators and shifts.

Disorganized Change Parts and Tools:

- How much time do your operators spend searching for the right timing screw or tracking down a tool for taking a star wheel off a machine? Scattered change parts and missing tools are surprisingly common on plant floors, and the accumulated search time adds up faster than most operators account for.

Lack of Standardized Procedures:

- When each operator approaches changeovers differently, results vary. One operator might complete a format change in 20 minutes while another takes 40, simply because they follow different sequences or skip certain verification steps.

Inconsistent Operator Training:

- Undertrained operators naturally take longer and make more errors during changeovers. Those errors often cascade into quality issues, line crashes, or the frustration of repeating setup steps that weren't done correctly the first time.

So How Can you Improve Your Changeovers?

Equipment Solutions for Faster Packaging Line Changeovers

Sometimes the most effective path to faster changeovers is addressing the equipment itself. Purpose-built solutions can eliminate complexity at the source rather than working around it.

Traditional guide rails often require loosening and repositioning brackets at multiple points along the conveyor—a time-consuming process prone to inconsistent results. Quick-adjust systems like Septimatech's EASY Adjust Rails allow operators to change lane widths from minimal adjustment locations, dramatically reducing both time and variability. These systems handle even tight radius corners and complex conveyor geometries with precise, repeatable adjustments.

Not all change parts are created equal. Timing screws, starwheels, and cap handling components designed with quick-connect features and clear format identification reduce swap time compared to generic or poorly designed alternatives that require extensive adjustment after installation.

Mobile carts that hold all change parts, tools, and documentation for a specific format allow operators to wheel everything to the line at once. Septimatech's 5S-oriented storage and changeover carts keep components organized, protected, and ready for immediate deployment.

How to Measure and Track Changeover Efficiency

What gets measured can lead to what gets improved. Tracking changeover performance reveals opportunities and verifies that changes are actually delivering results.

Changeover Time and OEE Metrics you should consider including in your KPIs.

OEE (Overall Equipment Effectiveness) measures availability, performance, and quality. Changeover time directly impacts the availability component: every minute in changeover reduces the percentage of planned time actually producing product. Adjustable guide rails play a particularly important role in improving these metrics.

- Changeover time = Duration from last good product to first good product of new run

- OEE availability = Percentage of planned production time the line is running

- Changeover frequency = Number of changeovers per shift or week

Tracking Improvement Over Time

Document changeover times by format, shift, and operator. Patterns will emerge—certain formats may consistently take longer, specific shifts may outperform others, or individual operators may have techniques worth sharing across the team.

Improve Changeover Efficiency

Contact Us Today to discuss your packaging line changeover needs.

The most effective changeover improvements share common characteristics: they're operator-friendly, repeatable, and work with existing equipment. You don't necessarily require complex automation or major capital investment to see meaningful results.

Quick-adjust guide rails, organized change part storage, standardized procedures, and consistent training can transform changeover performance on lines you already own. The key is focusing on solutions that eliminate variability and reduce the steps, tools, and decisions required during each format change.

Contact Septimatech to discuss your packaging line changeover needs or start a project.

FAQs about Improving Changeover Efficiency

How long should a typical packaging line changeover take?

Changeover duration varies based on line complexity and how different the formats are, but SMED methodology targets single-digit minutes (under ten minutes) as a benchmark for well-optimized changeovers. Many packaging operations achieve 5 - 15 minute changeovers after implementing systematic improvements.

Can changeover efficiency improve without replacing existing packaging equipment?

Yes. Aftermarket solutions like quick-adjust guide rails, organized change part storage, and standardized procedures can significantly reduce changeover time on existing lines. Often the biggest gains come from better organization and methods rather than new machinery.

What is the difference between automated and manual changeover solutions?

Manual solutions require operator adjustment using hand tools or quick-release mechanisms, while automated solutions use motors or actuators to reposition equipment. Manual quick-adjust systems often provide the best balance of cost, simplicity, and speed for many packaging operations.

How do quick-adjust guide rails reduce changeover time on packaging lines?

Quick-adjust guide rails allow operators to change conveyor lane widths from a single adjustment point rather than repositioning brackets along the entire line. This approach reduces adjustment steps from potentially dozens to just a few, while ensuring repeatable positioning every time.

What should a changeover cart include for packaging line format changes?

A well-designed changeover cart holds all change parts, tools, and reference materials for a specific format, organized and labeled so operators can transport everything to the line and begin immediately. This eliminates searching and ensures nothing gets left behind or forgotten.