Container Handling for Multiple Container Sizes on a Packaging Line:

Jan 27, 2026

Running five different bottle sizes on a single packaging line sounds efficient until the third changeover of the shift takes 45 minutes and production targets start slipping. The challenge isn't whether a line can handle multiple container sizes, it's whether it can switch between them without losing half the day to adjustments and troubleshooting.

Why Packaging Lines Need Flexibility for Multiple Container Sizes

In packaging operations, "multiple container sizes" refers to the variety of bottle heights, diameters, shapes, and formats that run on a single production line. A typical beverage line might handle everything from 8 oz bottles to 64 oz jugs, while a personal care operation could run round bottles, square containers, and oval shapes all in the same week.

Running dedicated lines for each container format is rarely practical. Many facilities don't have the floor space or budget for that approach, yet the multi-format packaging line market is estimated to grow to USD 11.4 billion by 2035. Well-designed changeover systems allow one line to handle a full product portfolio, which maximizes equipment utilization and meets diverse customer requirements without major capital investment.

Common Container Formats and Dimensions on Packaging Lines

Each container type presents unique handling characteristics that affect guide rail settings, timing screw selection, and change part requirements. Understanding these differences helps when planning changeover strategies.

Round containers are the most common format in beverage, food, and personal care packaging. The key dimensions are body diameter, base diameter, and overall height. Even small variations matter here. A difference of just a quarter inch in diameter requires different guide rail widths and timing screw configurations to maintain proper handling.

Square containers offer better shelf space efficiency, but they present stability challenges on conveyors. Unlike round bottles that can rotate freely, square formats require precise orientation control. Guide rails for square containers often need tighter tolerances to prevent products from turning sideways during transport.

Tapered containers are wider at one end than the other, which complicates handling because the effective diameter changes along the container height. Oval shapes add another variable entirely. Guide systems for these formats accommodate the container's widest dimension while preventing unwanted rotation.

Metal cans and rigid plastic containers typically handle well due to their consistent dimensions and structural stability. However, weight characteristics differ significantly from plastic bottles, which affects conveyor speeds and accumulation behavior. Heavier containers may require different guide rail pressures and conveyor settings. Cans can also be more prone to crushing if back pressure is heavy.

Cartons, pouches, and flexible packaging often require specialized handling equipment beyond standard guide rail systems. These formats may benefit from different conveyor types or dedicated packaging machinery rather than traditional bottle-handling solutions.

Challenges of Running Different Container Sizes

Switching between container formats sounds straightforward in theory. In practice, several operational problems can turn a 15-minute changeover into an hour-long ordeal.

Extended Downtime During Format Changeovers:

A format changeover involves adjusting multiple stations along the line. Infeed conveyors, fillers, cappers, labelers, and case packers all require modification when switching container sizes. On lines with manual adjustment systems, operators spend significant time walking the line, loosening bolts, repositioning rails, and tightening everything back down.

Inconsistent Manual Adjustments:

Two operators performing the same changeover often achieve different results. One might set guide rails slightly wider than another, leading to container wobble on the first shift and jams on the second. This inconsistency creates quality variations and makes troubleshooting difficult when problems arise.

Jams and Crashes from Incorrect Settings:

Misaligned guide rails or incorrectly sized change parts cause containers to tip, jam, or crash into downstream equipment. A single downed bottle in the wrong location can halt an entire line. These incidents waste product, damage equipment, and frustrate operators who then spend additional time clearing the jam and restarting production.

Disorganized Storage of Change Parts:

Change parts are the format-specific components swapped during changeovers. When these parts end up scattered across the plant floor, operators can't locate the correct star wheel or timing screw quickly. Damaged parts discovered mid-changeover create even longer delays and sometimes require costly emergency orders.

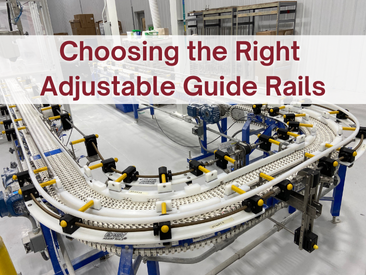

Guide Rail Systems for Multiple Container Sizes:

Guide rails physically guide and direct containers as they travel along conveyors. The right guide rail system dramatically reduces changeover time while improving container handling consistency across different formats.

Easy Adjust Guide Rail Systems

Septimatech’s Easy adjust systems uses mechanical adjusters to synchronize rail positions from an singular adjustment point. Instead of loosening dozens of brackets along a conveyor section, operators adjust from one or two locations. The rails return to the exact same width every time, which eliminates the variation that comes with manual setups.

Traditional manual systems require operators to adjust each bracket individually along the conveyor length. While less expensive initially, the labor and inconsistency costs add up quickly on lines with frequent changeovers. These systems work adequately for operations that rarely switch formats.

Automated Guide Rail Solutions

Motor-driven or servo-controlled rails when paired with a system like Easy Adjust Guide rails, adjust automatically based on recipe selection. Operators choose the container format from a control panel, and the system positions all rails accordingly. These solutions work well for high-volume lines with frequent format changes where speed and repeatability justify the higher equipment cost. With the packaging automation market reaching USD 169.58 billion by 2034, these systems are becoming more and more common.

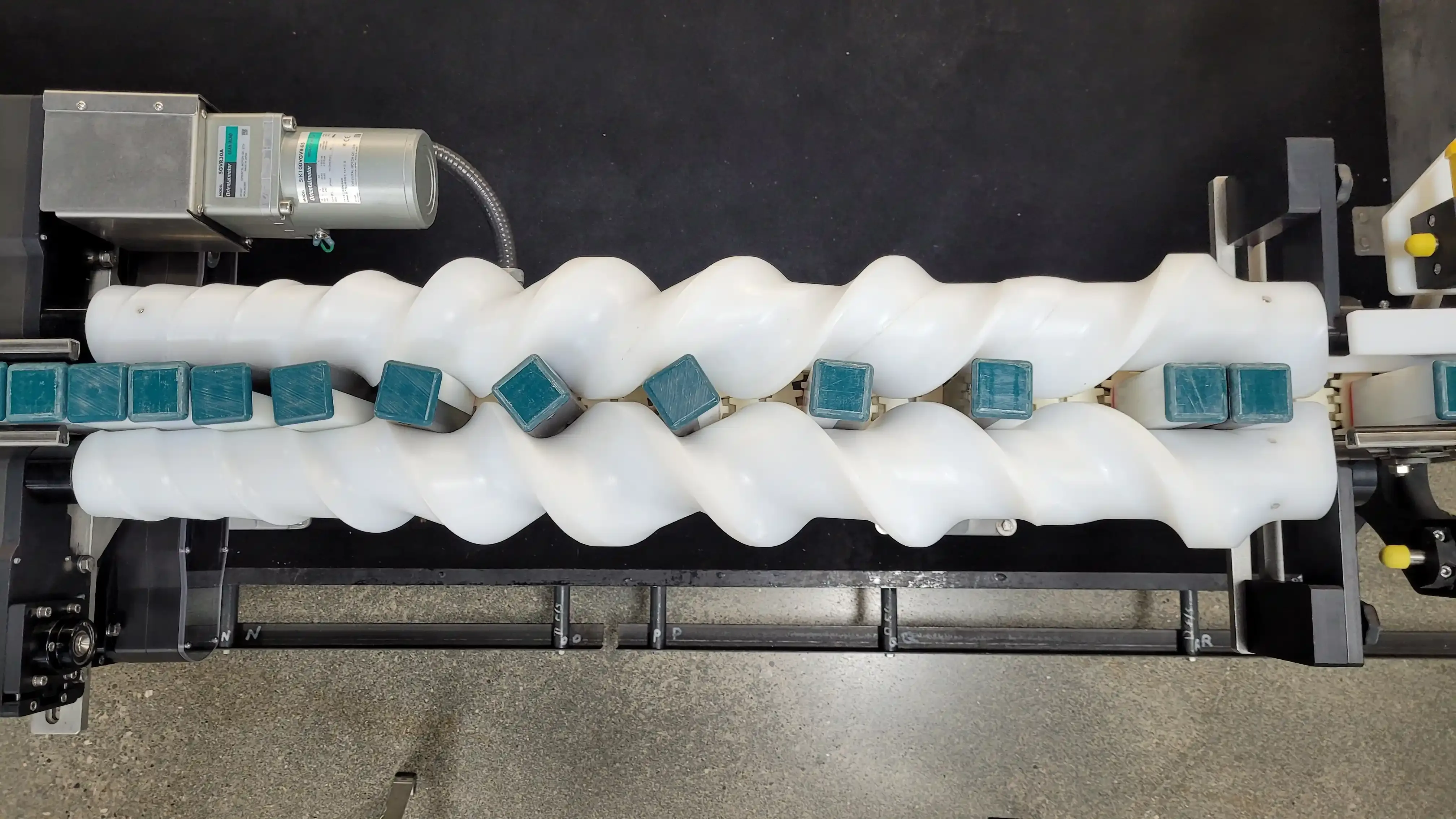

Timing Screws for Handling Diverse Container Measurements:

Timing screws, also called feed screws, control container spacing and positioning as products enter and exit filling, capping, or labeling stations. The screw's “pockets” catch each container and releases it at precisely the right moment for what ever the intended application is.

How Timing Screws Manage Different Container Sizes

The relationship between screw pitch and container diameter determines proper spacing. Screw pitch is the distance between threads on the screw. A screw designed for 3-inch diameter bottles won't correctly handle 2-inch containers because the spacing will be wrong, causing misfeeds at downstream equipment.

Quick-Change Timing Screw Configurations

Timing screws with quick-release mounting reduce the time required to swap between container formats. Rather than unbolting and realigning an entire screw assembly, operators can exchange screw sections in minutes. This approach keeps changeover time predictable and manageable.

Matching Timing Screws to Container Dimensions

Selecting the right timing screw starts with documenting container dimensions accurately. Height, body diameter, and base diameter all affect screw performance. Working with suppliers who understand your full container range helps ensure you get timing screws that handle your entire product portfolio without compromise.

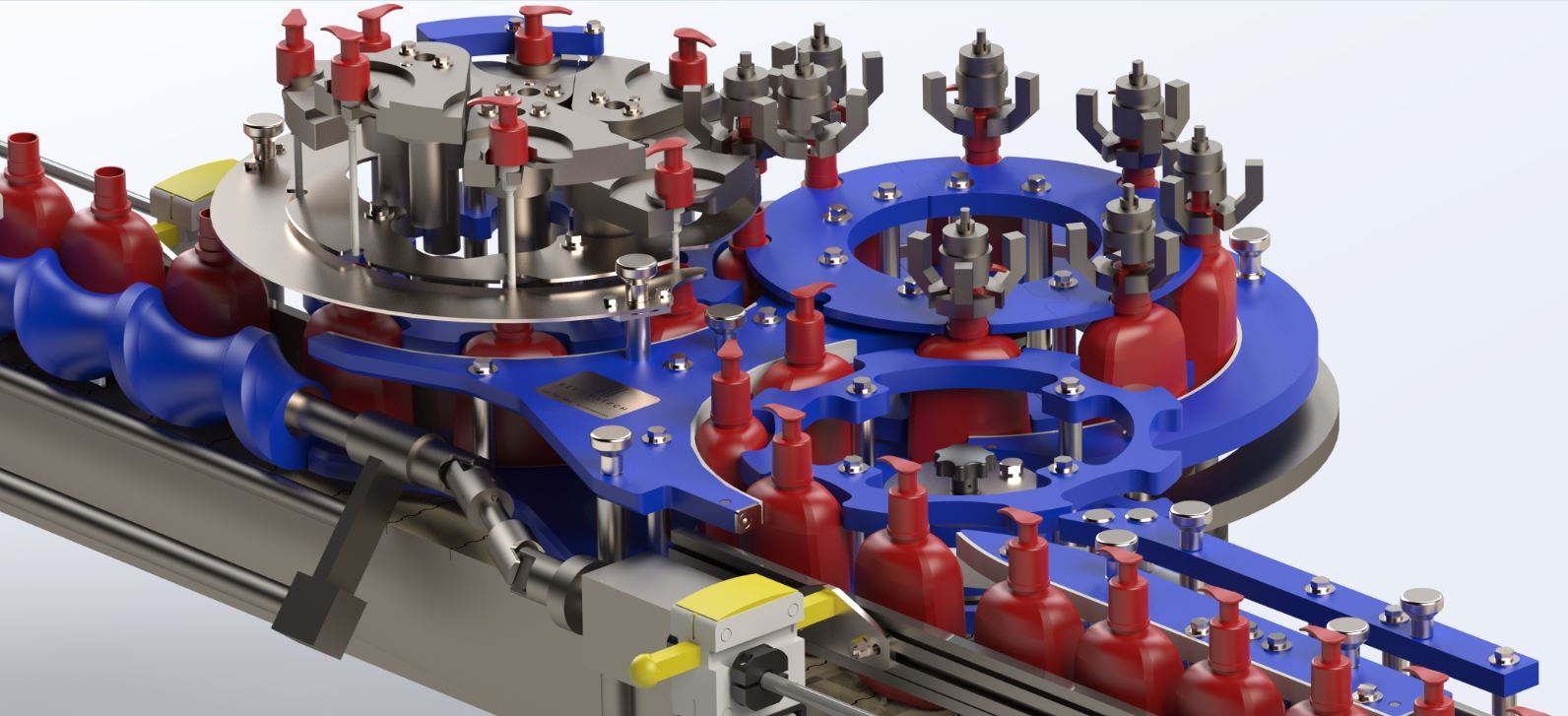

Change Parts for Quick Changeovers Across Container Formats:

Change parts are the removable, format-specific components that get swapped when switching container sizes. Understanding what changes and organizing those parts effectively impacts changeover speed directly.

- Star wheels: Pocket-style components that grip containers at specific diameters during filling or capping operations

- Gripper change parts: Clamping components sized to specific container bodies for secure handling

- Cap handling components: Chutes and sorters configured for different closure sizes and styles

- Bottle inverter configurations: Twist sections designed for specific container heights and shapes

Downed Bottle Reject Systems

Downed bottle reject systems automatically remove fallen or mispositioned containers before they cause downstream jams. Height-specific settings ensure the system detects downed bottles without interfering with properly oriented containers. These mechanical systems operate continuously without requiring operator intervention.

Tip: When ordering change parts, document container height, body diameter, base diameter, neck finish diameter, and weight. Accurate measurements ensure proper fit and prevent costly reorders.

Organizing and Storing Change Parts for Multiple Container Sizes:

Even the best change parts become a liability if operators can't find them quickly. Proper storage protects components from damage and speeds retrieval during changeovers.

5S Storage Systems for Change Parts

The 5S methodology provides a framework for organizing change parts. The five S's stand for Sort, Set in Order, Shine, Standardize, and Sustain. Shadow boards with labeled outlines show exactly where each component belongs, making missing parts immediately obvious. When a part isn't in its designated spot, everyone knows something is wrong.

Changeover Carts for Format-Specific Components

Mobile carts that group all change parts for a specific container size streamline the changeover process. Operators wheel the cart to the line, swap components, and return the previous format's parts to their designated cart. This approach keeps parts organized and reduces the walking time that adds up during changeovers.

Labeling and Inventory Management

Clear labeling by container format helps operators quickly identify correct components. Labeling by format name rather than just part number makes selection faster and reduces errors. Regular inventory checks prevent the unpleasant surprise of discovering a damaged or missing part mid-changeover.

Lines with multiple changeovers per shift benefit most from quick-adjust solutions. The labor savings and reduced downtime, with potential documented 94% reductions in changeover times, often justify higher initial equipment costs. Lines with infrequent changeovers may find manual systems adequate, though even occasional changeovers benefit from organized storage and clear procedures.

Choosing the right changeover solutions starts with understanding specific production requirements. A line running three similar bottle sizes has different considerations than one handling fifteen diverse formats. Working with a container handling solutions provider like Septimatech will help you with these considerations.

Document the full range of containers your line handles and provide this to us. We can suggest potential changeover efficiency that will improve your container handling, boost throughput, and give more life to existing machinery:

- Minimum and maximum heights across all products

- Smallest and largest diameters in your portfolio

- Shape variations including round, square, oval, and tapered

- Weight differences between lightest and heaviest containers