What are Change Parts for Packaging Machinery?

May 13, 2025

In today’s fast-paced packaging environments, speed and flexibility are essential. Manufacturers must be able to switch between SKUs quickly without sacrificing accuracy or uptime. That’s where Change Parts come in—these precision-engineered components are critical to maximizing performance, flexibility, and reliability across your entire packaging line.

Whether you're running fillers, cappers, labelers, or other high-speed machines, change parts are the key to achieving smooth and repeatable changeovers.

What Are Change Parts?

Change parts are interchangeable parts of packaging machines, allowing the packaging machine to handle different containers, caps, or formats simply by performing a "changeover" to a different set of parts. These parts are unique to each product, ensuring containers are aligned, spaced, and guided precisely through every stage of the packaging process.

No matter the container type - a round bottle of cold brew coffee or a square jar of vitamins - aftermarket change parts make your packaging machinery flexible, without incurring the often enormous capital costs of acquiring new equipment.

Where Are Change Parts Generally Used?

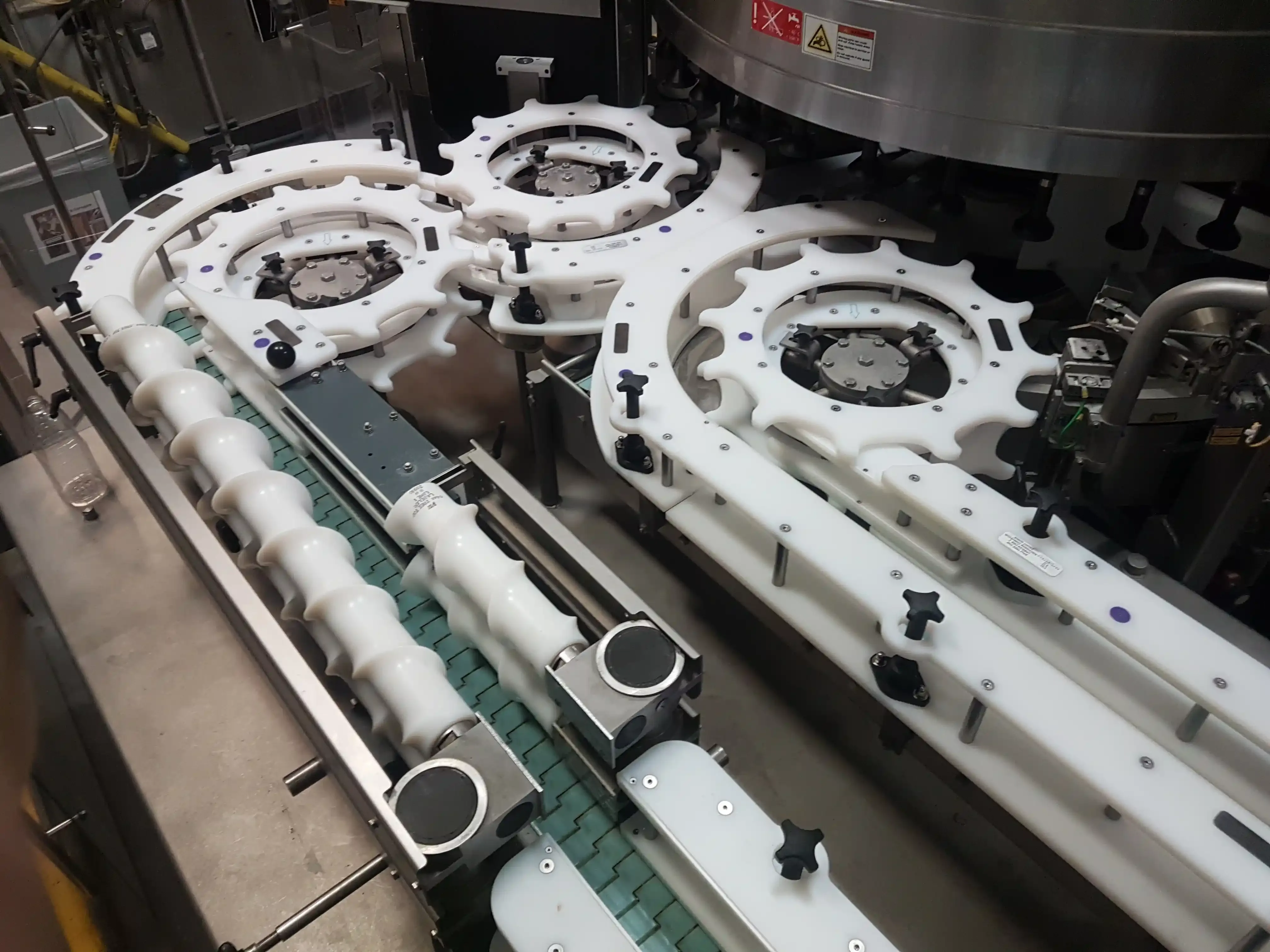

Although most commonly found on machines, like fillers and cappers, change parts can be found in many forms across a variety of packaging systems, including:

- Fillers – Used for filling bottles, change parts precisely align containers under nozzles for accurate dispensing of product into the container.

- Cappers – Parts like cap chucks secure caps and closures with precision torque specifications.

- Labelers – Position containers for correct label application.

- Timing Screws & Feed Screws – These systems, also known as worms and scrolls, are used to control spacing and product orientation before they enter packaging machines like fillers and cappers.

- De-puckers & Unscramblers – These change parts orient and feed containers onto the line from a starting source.

- Bottle Reject Systems - In-line systems responsible for rejecting downed bottles on conveyors between packaging machinery.

Regardless of the location of these parts on the packaging line, each type of change part can play a critical role in maintaining productivity, quality, and consistency on a line.

Change Parts Have Many Names:

Change parts are integrated across a variety of packaging systems, and each part plays a critical role in maintaining productivity, quality, and consistency.

Below are just a few of the parts that are frequently changed out on packaging machines:

- Starwheels - Transfers containers between machine sections (filler to capper for example) with perfect timing and consistent handling.

- Feed Screws - Positions and times containers for precise alignment and spacing for specific applications on packaging lines (feeding containers into a filler machine using an "Infeed" feedscrew).

- Capping Chucks - Applies caps onto containers for different cap types and sizes.

- Label Handling Parts - Accurate label application onto bottles & other containers across various shapes and sizes.

- Bottle Plates, Body Locators, Positioners - Provide precise container alignment and stability throughout filling, capping, and labelling.

- Rinser, Washer, & Filler Neck Grippers - Ensures precise positioning of various bottle shapes and sizes for rinsing washing and filling.

Who Benefits from Change Parts?

Change parts can be found on machines across many industries. In all industries, change parts are what make line flexibility possible. Below are just a few of the industries that change parts can be found in:

- Beverage & Brewing – Handle multiple bottle formats, including cans, glass, and PET

- Pharma & Nutraceuticals – Ensure accurate and sterile handling of vials and droppers

- Cosmetics & Personal Care – Handle tubes, pumps, and unique containers

- Contract Packagers – Switch frequently between short-run and specialty products

✅ Faster Changeovers

Quickly adapt to new container formats with minimal downtime, maximizing your O.E.E. (Overall Equipment Effectiveness).

✅ Improved Accuracy

Ensure precise container handling, reducing spills, jams, and costly misalignments.

✅ Reduced Operator Error

Many change parts are designed for tool-less installation, and feature color coding or part numbers to guide operators through changeovers.

✅ Extended Equipment Life

Well-designed change parts reduce wear on machinery by maintaining alignment and reducing mechanical stress.

If your packaging line handles multiple product types or container formats, change parts are an integral part of your line. Improving them can unlock efficiency, accuracy, and adaptability, helping your operations keep pace with demand without costly new machinery.

At Septimatech, we specialize in designing change parts that integrate seamlessly with your existing equipment, regardless of the machine make/model. Our parts are engineered for performance, built for durability, and supported for life.