- Blog

- /

Keep Production Moving: Eliminate Downtime with a Downed Bottle Reject System

Jul 10, 2025

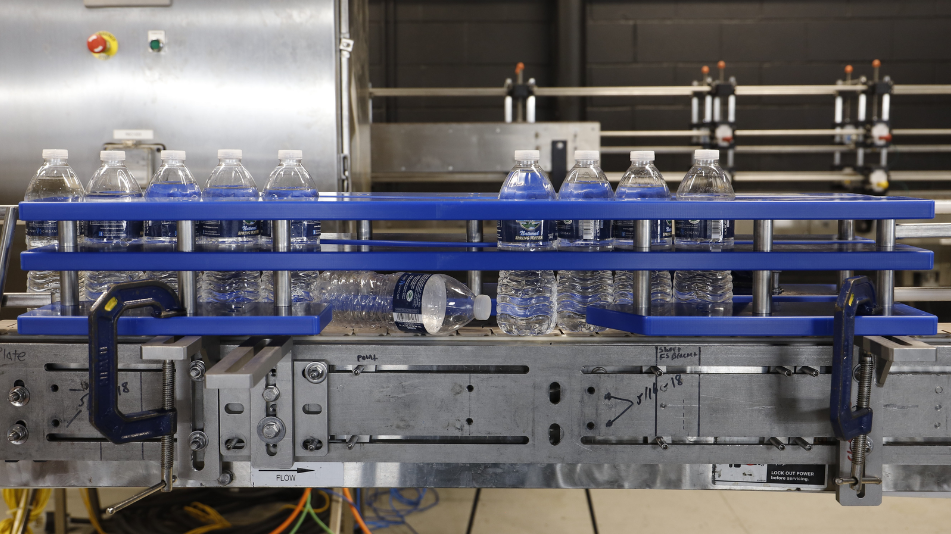

In high-speed packaging environments, even a single downed bottle can lead to costly line stoppages, product waste, and safety concerns. That’s why leading manufacturers turn to reliable automated bottle rejection to keep operations running at peak performance.

This is where Septimatech's Downed Bottle Reject System can provide a simple, yet extremely valuable solution.

Automated Detection and Removal of Downed Bottles:

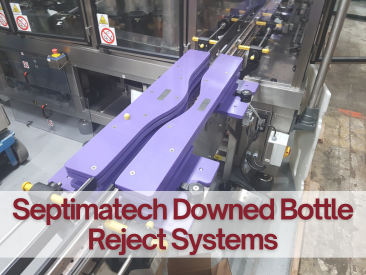

Septimatech’s Downed Bottle Reject System uses a simple mechanical system to automatically detect and remove only the fallen containers, without interrupting the flow of upright products or use of complex pneumatic rejection systems. This precision solution improves line reliability and reduces dependency on manual process, meaning your operators will be free to tackle more value-add tasks.

Key Features Include:

Identifies downed containers in a simple, mechanical manner, with no complex electrical or pneumatic requirements.

Removes only fallen bottles with no impact to upright products, ensuring that the flow of containers continues smoothly down your packaging/production line.

Septimatech's Downed Bottle Reject System can be easily integrated onto an existing conveyor. Quick change mounting options allow for easy removal for cleaning when required.

Engineered for reliability and reduced upkeep, this system is simple and uses little to no moving parts, meaning there is no need for lubrication or any other type of mechanical upkeep.

Flexible for Any Container or Industry

You could be packaging PET bottles, glass vials, cartons, or other rigid containers. No matter the container type, Septimatech's Downed Bottle Reject System is designed to adapt. It can support a broad range containers from various industries, including:

- Beverage

- Food

- Pharmaceutical

- Household Products

- Personal Care & Cosmetics

No matter the container shape or material, our downed bottle reject system ensures simple and effective removal of fallen containers to minimize disruption and maintain throughput.

Proven Results on a Global Scale.

With installations worldwide, Septimatech’s Downed Bottle Reject System has helped packaging lines increase uptime, reduce waste, and enhance operator safety. Customers report fewer stoppages and increased uptime thanks to the system’s accurate, responsive performance.

If your packaging line is frequently interrupted by downed containers, it may be time to consider a smarter solution. The Downed Bottle Reject System is a simple upgrade with significant impact, keeping your production flowing, your equipment and operators safe, and your output consistent.

Contact Us Today

to learn more about how Septimatech's Downed Bottle Reject can be the solution to increased uptime that you have been missing.